Fluidization Process in Fluid Bed Dryers

Understanding the Dynamics of Fluidization Process in Fluid Bed Dryers

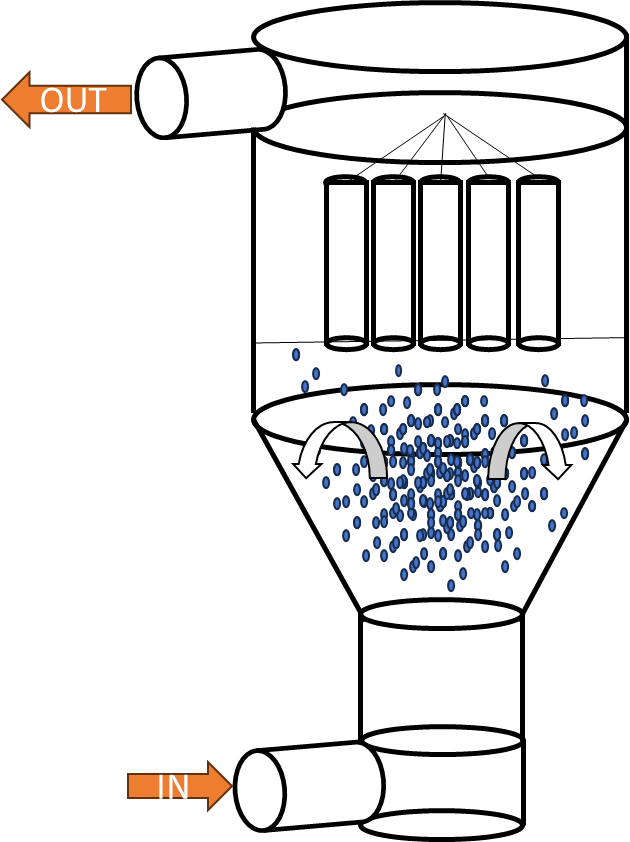

In a batch fluid-bed dryer (FBD), dry hot air is passed upward through a perforated distribution plate at the base of a stainless-steel vessel, suspending (fluidizing) the moist solid particles. Initially the particles rest on the plate, but as airflow increases, the upward drag overcomes gravity and the bed “boils” – particles become suspended and mobile, behaving like a fluid. This fluidization produces highly turbulent mixing: each particle is uniformly contacted by hot air, maximizing heat and mass transfer. Moisture evaporates rapidly and is carried out with the exhaust air. The fluidized state continues until moisture is removed; the bed then de-fluidizes as airflow is reduced. In practice, batch FBDs may operate in stages (e.g. fast fluidization, bubbling regimes) to optimize drying rate and minimize attrition. Key features include a removable perforated “bowl” or bottom chamber where air is introduced, a retarding/process chamber above it where the bed expands, and an expansion chamber with filter housings (to collect fines) at the top【48†】. The uniform suspension of particles ensures all material is subjected to essentially identical drying conditions. This rapid solid‑gas contact makes FBDs much faster (orders of magnitude) than static dryers, with all particles remaining free-flowing and mixing continuously.

Advantages by Dosage Form

Granules (wet granulation and drying):

Fluid-bed processing produces uniform, dense granules with excellent flow and compressibility. By integrating wet granulation and drying in one vessel, the fluid bed yields homogeneously mixed granules free of large lumps. The result is narrow particle-size distribution and low dust. Because drying occurs concurrently with granulation, heat- and shear-sensitive materials can be processed gently. High gas–solid contact gives strong heat and mass transfer, so drying is fast and efficient (short cycle times). Users report lower energy use and maintenance costs than trays or high-shear dryers. Fluid-bed granulation also avoids localized over wetting or overmixing: the spray rate and air flow are tightly controlled to yield consistent binder distribution. In summary, FBDs produce high-quality granules for tablets/capsules – uniform moisture, density and strength, with minimal fines or dust.

Tablets (coating and granulation support):

In tablet manufacture, FBDs are often used for drug-layering on cores or for granulation of tablets. Fluidization allows uniform coating of tablet cores or pellets using bottom-spray (Würster) technology, giving highly reproducible film layers. Because the spray nozzle is inside the fluidized bed (Würster process), each core receives the same exposure to coating solution and drying air, yielding excellent uniformity and consistent release profiles. Compared to conventional coating pans, fluid-bed coater operation is faster and easier to scale-up. The gentle fluid motion minimizes mechanical stresses on delicate tablets. Moreover, using the same vessel for granulation and coating reduces equipment footprint. Granules intended for direct compression are also easily dried in a fluid bed to optimal tablet moisture content; studies show FBD drying of tablet granulations can be an order of magnitude faster than tray drying. In short, for tablets FBDs offer uniform coating, fast drying, and one-step granulation/drying, improving throughput and product quality.

Capsules 💊 (pellets and multi-particulates):

For capsule products, fluid-bed dryers are indispensable for producing drug-layered pellets and multi-particulates. Spherical starter cores (e.g. sugar or microcrystalline cellulose beads) can be fluidized and sprayed with APIs or functional coatings. The result is spherical pellets with narrow size distribution, high bulk density and low hygroscopicity. Key advantages include precise control of drug loading and controlled-release layering. Pellets allow combination of multiple actives or release profiles in one capsule. Also, pelletized fill offers dose flexibility (e.g. easy dose titration by capsule content) and easier swallowing. Fluid-bed layering yields thin, uniform films – e.g. sustained- or enteric-release polymer coats – with minimal agglomeration. Moreover, because drying and coating happen simultaneously, the throughput is high. In summary, FBDs enable efficient manufacture of capsule-fill pellets with excellent uniformity, controlled-release properties, and patient-friendly dosage forms.

Engineering Overview of FBD Equipment

A modern batch FBD system comprises an Air Handling Unit (AHU) linked to a vertical main tower with product vessel, plus exhaust processing (see figure below). The AHU supplies clean, conditioned air; typical components include multi-stage filtration, fans, dehumidification, heating, and humidification as needed. Air first passes through coarse filters (e.g. G4 prefilter for >10 μm) and fine filters (e.g. 3 μm / 5μm post-filter) to remove particulates and contaminants. Final filtration happens though dedicated HEPA filter (~0.3 μm) bank. Dehumidification is achieved via either cooled condenser coils or a regenerative desiccant wheel; e.g. a silica-gel rotor (desiccant wheel) can reduce air humidity to very low levels before heating. Conversely, humidification (if required for process control) can be done by controlled steam injection. After filtration and humidity control, the air enters the fan/blower. Most FBDs use a centrifugal blower (backward-curved impeller) to draw ambient air through the filters and force it into the heater chamber. The heater section may use electric heating coils or steam-heated pipes; fluid-bed systems often allow choice of electric, steam, or thermal oil heating for flexibility.

Figure: Labeled vertical fluid-bed dryer (expansion chamber at top, retarding chamber above the product container, base/bowl at bottom). Key parts include (top to bottom) expansion/filter chamber, retarding chamber (fluidization zone), inflatable gasket, product container, distributor plate, and bottom bowl.

The main tower (stainless-steel) consists of: the bottom bowl (air plenum), the product container (vessel), an inflatable gasket seal interface, the process/retarding chamber, and the expansion chamber with filter housings. The bowl holds a clamp-secured perforated air distributor plate that supports the bed. The product container (often on a trolley) holds the wet material. Removable sight glasses and sampling ports are typically provided for observation and in-process checks. Above the vessel, the retarding chamber allows the bed to expand. As air rises it carries fines into the expansion chamber, where filter bags capture dust. These filter bags are periodically “shaken” by pneumatic actuators to release the cake (dust) layer back into the process. After the filter chamber, the exhaust flows through outlet ducts and dampers into the exhaust blower/fan, then to final exhaust (venting or emission control).

Alongside these, a secondary exhaust filter (optional) may be provided to capture any particles escaping the main filters. In facilities using organic solvents (e.g. IPA) in coatings/granulation, a wet scrubber or thermal oxidizer is often used downstream of the exhaust to remove VOCs and odors, ensuring emissions comply with safety limits. High-VOC peaks (often exceeding 100% of the lower explosive limit in batch processes) necessitate dilution or catalytic/thermal destruction to prevent explosion risks.

Filtration: In summary, air enters through stages of filtration – typically a prefilter (e.g. G4), a fine post-filter (~1 μm), and a HEPA or ULPA filter for sterilizing grade cleanliness. The bed’s own filter bags remove entrained fines; these are usually full-length, reverse-pulse cleanable filter cartridges or bags inside the expansion chamber. Automatic pulse-jet or mechanical shakers prevent bag clogging, enabling continuous operation. Cleanability and containment are key – many modern FBDs use disposable filter liners or bag-in/bag-out housings to minimize operator exposure to active dust.

Blowers: As noted, a centrifugal blower supplies the air. These are often rated for high flow (hundreds to thousands of CFM) and high pressure to overcome system resistance (filters, particulate load). Blower impellers are dynamically balanced (often backward-curved) for smooth airflow. Shaft-mounted motors or integrated drive packages are used. VFD (variable-frequency drive) controls allow precise tuning of airflow (thus fluidization velocity), and soft-start features reduce surge stress.

🔥Heating/ ❄️Cooling: The AHU houses the heater; common choices are electric coil heaters or steam coils. Electric coils offer precise control, whereas steam allows higher temperature with uniform heating. Some designs include a heat-recovery coil to capture exhaust heat and preheat inlet air (improving efficiency). Cooling is rarely needed in an FBD, as the goal is high inlet temperature. However, if too much heat builds up (e.g. in prolonged drying), some systems can inject ambient or chilled water spray upstream to modulate air temperature.

Humidity Control: Many FBD processes are sensitive to humidity. Besides the dehumidifiers mentioned above, some plants use dedicated drying air recirculation with a heated desiccant wheel – a closed-loop system where exhaust air is dried and reheated, minimizing fresh air load. Conversely, if the incoming air is extremely dry, a controlled humidifier (steam or water spray) can be added to stabilize RH. Overall, the system design aims to deliver air at the set point of flow rate, temperature and dew-point.

Sensors & Automation Architecture:

Modern batch FBDs are highly instrumented. Typical sensors include:

- Temperature: Multiple RTDs/thermocouples measure inlet and outlet air temperatures and bed (product) temperature. A Pt100 probe is often inserted into the material to directly monitor product temperature. These allow detection of end-point when product reaches target temperature/moisture.

- Humidity/Dew Point: A chilled-mirror dew-point sensor or capacitive humidity probe monitors relative humidity (RH) of inlet or outlet air. Controlling RH (or dew point) is critical for precise moisture removal. For example, Vaisala DRYCAP probes are commonly used for low-humidity measurement in drying applications. Dew-point transmitters (e.g. Sensorex, Michell) may also be included to optimize drying cycles.

- Airflow: Flow is often measured indirectly via differential pressure across a calibrated orifice, pitot tube, or a thermal mass flow sensor. The FBD’s control system uses this to maintain the set superficial gas velocity (just above minimum fluidization velocity). In laboratory R&D units, vane or thermal anemometers in the plenum can give direct flow readouts.

- Pressure: Differential pressure gauges across the distributor plate verify proper bed pressure drop. A pressure sensor on the filter bags monitors clogging. Inlet/outlet static pressure may also be logged.

- Level/Load: Some systems have an inductive or pressure-based sensor to estimate bed level or fill weight, useful for endpoint determination.

- Spray Control: For granulation/coating, the spray pump is instrumented. Flow meters or mass flow controllers ensure the binder/spray liquid rate is at the set value. The atomizing nozzle is usually two-fluid (compressed air) or pressure-type; solenoid valves on the spray lines allow on/off control. Nozzle pressure and spray angle may be fixed per design.

All these sensors feed into a PLC-based control system. Operators interact via an HMI touchscreen, where all Critical Process Parameters (CPPs) are set and monitored. The PLC executes recipes controlling heaters, fans, valves, and pumps. Interlocks (e.g. against lid-open or filter saturation) ensure safety. For example, UPMACH notes its FBD features PLC automatic control with full data logging: all process parameters are recorded and printable to meet GMP documentation. Modern FBDs support SCADA or DCS networks for centralized monitoring. Control architectures often use Ethernet/IP or Modbus protocols. Control panels include batch controllers with built-in recipe management, trend displays and alarm logging. Critical setpoints (inlet T, airflow, spray rate, bed temperature, outlet RH) are continuously trended. An audit trail is maintained on the control system (typically 21 CFR Part 11 compliant) so that any operator or automatic parameter change is timestamped and unmodifiable. Alarm thresholds are set for out-of-range CPPs (e.g. inlet T high, filter ΔP high, product T above limit); alarms are logged and can trigger shut-down or hold steps.

Materials and Coating/Layering Technologies

Batch FBDs process a wide range of solid materials. Common materials include: spray-granulated powders, wet-mass granules, nonpareil pellets (sugar, MCC), extrudate beads, spray-coated layered particles, and tablet cores/pellets. Examples: lactose/starch granulations, cellulose-based granules, drug-layered sugar spheres, or coated pellets for extended release. FBD granulators handle products ranging from very fine powders (30–50 µm) to small granules (100–500 µm) or multi-layered pellets (up to several mm). The vessel may be fitted with different inserts (e.g. Wurster coating cylinder) for tablet or pellet coating.

For layering or coating applications, FBDs use specialized spray nozzles. The two main designs are:

- Bottom (Würster) spray: A spray nozzle is positioned at the bottom center inside a tubular insert. As shown in [33], air is drawn up through the central tube, entraining particles up through the insert (forming a convection current), where they encounter the spray from below. The mixed spray and particles then move out into the expansion chamber to dry, repeatedly cycling. This Würster process gives very high coating quality and uniformity: every particle has essentially the same residence time in the spray zone. Thicker or multiple polymer coats (enteric, sustained-release) can be applied without agglomeration. It works for aqueous or organic coatings and is excellent for small cores or pellet layering (e.g. drug layering).

- Tangential (rotor) spray: A motor-driven disk at the base centrifugally lifts particles to the spray zone. The nozzles are directed tangentially and/or axially onto the rotating bed. As [33] describes, the high kinetic energy induces rapid mixing and even coating, particularly for building up large coated pellets. The rotor’s agitation prevents wet massing and improves coating on relatively larger particles. It is well-suited for powder layering and film coating of pellets, providing narrow size distribution and spherical morphology.

- Top spray: In some granulation modes, one or more nozzles spray from above onto the fluidized bed (sometimes combined with bed oscillation). This is mainly used for large-scale wet granulation (growing granules by spraying binder). However, top spray is less common for precision coating of tablets/pellets, since the spray falls through the bed and can cause uneven coating.

Typical atomizing nozzles in FBDs are either two-fluid (compressed air) for fine mist or pressure-type (hydraulic) nozzles. Nozzle selection depends on required droplet size and binder viscosity. Spray pumps are usually peristaltic or piston pumps with servo drives for precise rate control (ml/min). Often the nozzle air cap design is chosen to avoid clogging by solids. In high-solid loading processes, inlet air pressures and flow are balanced to maintain good atomization while keeping bed intact.

Materials handled: In pharmaceutical OSD, fluid beds process materials like lactose/starch granulations, microcrystalline cellulose beads, spray-dried lactoses, plastic-coated granules, etc. They also handle pharmaceutical pellet cores (sugar spheres, Opadry® beads, or extruded beads) for multi-layering. High-API-load granules (e.g. layered nanocrystals) are supported by gentle fluidization. Cellulosic fibers, effervescent precursors, vitamins, and heat-sensitive biologics (e.g. probiotics) can also be dried in fluid beds.

Instrumentation and Process Control

Air Conditioning and Flow: The inlet airflow is setpoint-controlled via the blower VFD. A flow or pressure sensor ensures the velocity is above minimum fluidization. Typical fluidizing velocities are on the order of 2–4 m/s (2–4 times the minimum fluidization velocity) to avoid slugging. The inlet air temperature is controlled by the heater, using feedback from an inlet thermocouple. Modern controllers can also manage multi-stage heating (gradually ramping temperatures to avoid case hardening).

Humidity/Dew Point Control: Relative humidity (RH) is monitored by a probe in the drying air circuit. The PLC can adjust dehumidifier operation or inlet airflow to maintain target RH, which is critical for end-point determination. A dew-point sensor on the inlet air can trigger on/off dehumidification. Controllers may also have logic to add humidity (via steam injection) if RH is too low, although this is less common.

Product Temperature: A temperature probe (e.g. Pt100) is immersed in the bed to track product temperature; this is a primary CPP. The fluid bed’s endpoint is usually when product temperature approaches inlet air temperature (indicating dryness). The PLC can compare product vs. outlet air temperature to infer moisture removal. Advanced systems may use a model (or a soft sensor) that predicts moisture content from these readings.

Spray Rate and Atomization: In granulation/coating modes, the binder or coating solution is metered by a calibrated pump. The PLC controls the pump speed to achieve a set spray rate (e.g. mL/min). Simultaneously, nozzle atomizing air pressure (for two-fluid nozzles) is regulated (often via a pressure regulator) and monitored. Deviations (e.g. nozzle clog) can raise alarms. Flow meters on the spray lines are rare; instead, infusion pump feedback and calibrated nozzle specs are used.

Alarms and Safety Interlocks: Typical alarms include: High/low inlet air temp, high product temp (to prevent overheating), high outlet humidity (indicating saturated load), fan failure, heater fault, filter ΔP too high (clogged filter), door open (interlock), over-pressure (breach conditions), and coating liquid empty. Most systems include explosion relief vents on the vessel and ducting for safe failure. The PLC incorporates interlocks for safety (e.g. stopping spray if pressure spikes).

All process data are logged (historic trending) by either the PLC or a connected SCADA historian. The data and alarms are archived in compliance with GMP. Modern systems use digital communication protocols, and many FBDs now include Ethernet/IP or Profi-net for integration into plant-wide MES/SCADA networks.

Automation and Data Handling

Fluid-bed dryers in pharma are fully GMP-compliant automated systems. A typical automation architecture is PLC with an HMI/SCADA interface: Recipes (process steps and setpoints) are uploaded to the PLC, and operators run batches via the touchscreen (e.g. Siemens or Allen-Bradley panel). Real-time data (temperatures, flows, RH, pressures, motor speeds, etc.) are displayed graphically. All CPP trends are recorded with time stamps. Alarm events generate notifications and are logged. Batch reports are automatically compiled and can be printed or exported. Audit trails record any manual changes to recipes or setpoints, as required by 21 CFR 11.

Trend-analysis tools allow engineers to review moisture curves and heater duty, for example. Some advanced installations add PAT (Process Analytical Technology) instruments: for instance, inline NIR or Raman probes may be mounted on the product chamber to directly monitor moisture or coating thickness. In addition, modern FBDs may utilize advanced software (CFD or AI-based algorithms) to predict the end-point and optimize the drying profile. For example, computational fluid dynamics has been used to validate airflow patterns and ensure uniform fluidization in custom designs.

Alarms are tiered: an operational alarm (e.g. heater heater fails) will pause the batch and trigger a safe shutdown sequence. A critical alarm (e.g. out-of-spec product temp) may abort the process. All alarms feed into a supervisory SCADA system if connected. Integration with plant MES allows automatic shift change handoffs and electronic signatures.

Innovations and Recent Trends

Recent years have seen several innovations in FBD engineering design:

- Enhanced Coater Inserts: New Würster inserts (e.g. Glatt UniCone or Hüttlin DiskJet) offer improved flow and scale-up. These introduce a combination of inner and outer compartments to optimize coating uniformity at all scales. Scale-up software (digital twins) now helps scale fluid beds without extensive pilot trials.

- Containment and Safety: As OSD APIs become more potent, high-containment designs (closed-chamber fluid beds with glovebox isolation) are more common. Explosion-proof fans, pressure-shock resistant vessels, and automatic purge routines (e.g. nitrogen blanketing) improve safety. Inline E-stop and vent valves mitigate dust explosion hazards.

- Energy and Sustainability: Co-generation and heat-recovery schemes are increasingly used. For example, some systems recirculate exhaust heat to preheat incoming air. Advanced dehumidifiers (optimized silica-gel wheels) lower energy by recycling air. Water/solvent recovery options are added to capture evaporated solvents (e.g. from granulation binders) rather than venting them.

- Smart Sensors & Control: Wireless sensor networks and digital transmitters (MODBUS/IO-Link) are replacing analog 4–20 mA loops for flexibility and reduced wiring. High-accuracy dewpoint probes (e.g. Vaisala DRYCAP) ensure stable control even at very low moisture levels. Some units now employ adaptive control algorithms or model-predictive control to reduce overshoot of drying. Predictive maintenance (monitoring blower vibration, filter health via ΔP trends, motor amperage) helps avoid downtime.

- Integrated Processing: “Continuous” fluid bed systems (with multiple chambers) are being applied even in batch mode to shorten cycle time. Fully enclosed CIP (clean-in-place) loops can clean the bowl and tower with minimal manual intervention.

- Data Connectivity: The latest FBDs can connect to manufacturing execution systems (MES) and data historians. Cloud analytics for process optimization are emerging (e.g. AI routines to correlate inlet/outlet humidity curves with drying efficiency). Real-time dashboards and remote monitoring (validated VPN access) allow engineers to review batches from anywhere in the facility.

In summary, modern batch fluid-bed dryers combine sophisticated engineering – robust air handling, multi-stage filtration, precise heating/cooling, and advanced sensors – with automated control systems (PLC/SCADA) to achieve gentle, uniform drying and coating of pharmaceutical solids. Continuous R&D (CFD modelling, improved nozzle designs, smart controls) keeps improving performance, efficiency, and data integrity, ensuring these machines meet the latest pharmaceutical quality and safety standards.